Spool and Hub Metrologies with Dynamic Laser Scanning

DOF SUBSEA

OVerview

Spool and Hub Metrologies with Dynamic Laser Scanning

Customer: DOF Subsea

Industry: Offshore Energy

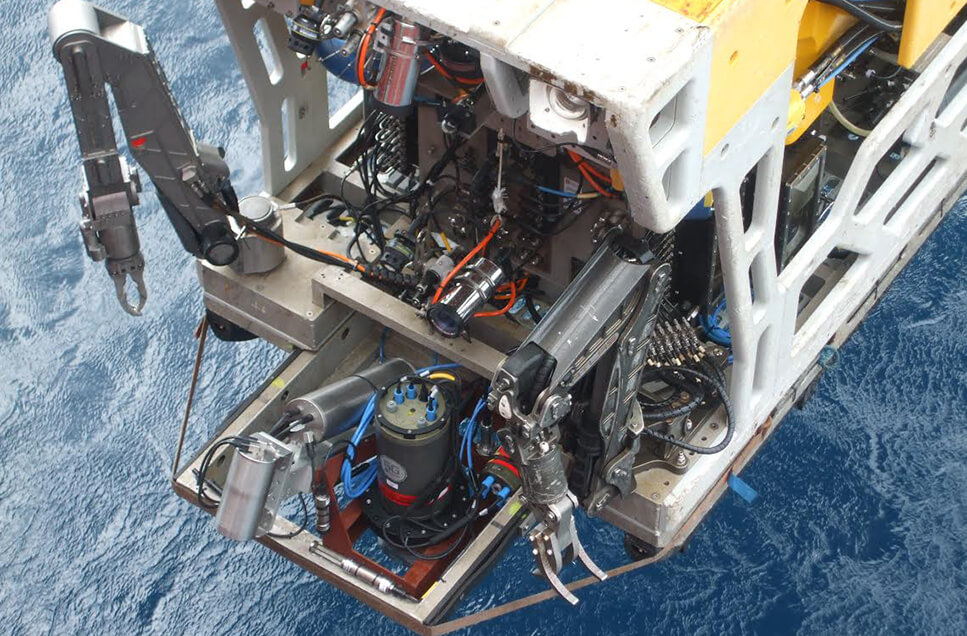

Vehicle Used: Triton XL ROV

Voyis Products Used: Insight Pro

Summary: In December 2016 at The Underwater Centre in Fort William, Scotland, DOF Subsea (DOF) arranged a demonstration of dynamic underwater laser scanning as a replacement for traditional metrology techniques. The demo showcased Voyis’ underwater laser scanner, the Insight Pro, and Sonardyne’s inertial navigation sensor, SPRINT; Syrinx DVL and 6G acoustics. Seatronics, channel partner for Voyis and provider of Sonardyne rental equipment, provided sensors and project/technician support.

The Project

Traditional metrology campaigns using Long BaseLine (LBL) acoustics and photogrammetry demand significant vessel and ROV time. LBL requires physical interaction with the subsea assets and photogrammetry is unable to provide real-time results. The goal of the demo was to quantify the operational time reduction and accuracy of dynamic laser scanning for subsea metrology.

[Dynamic Laser Scanning] has revolutionized the capability to perform mobile metrology operations in a timescale previously unattainable.

The Process

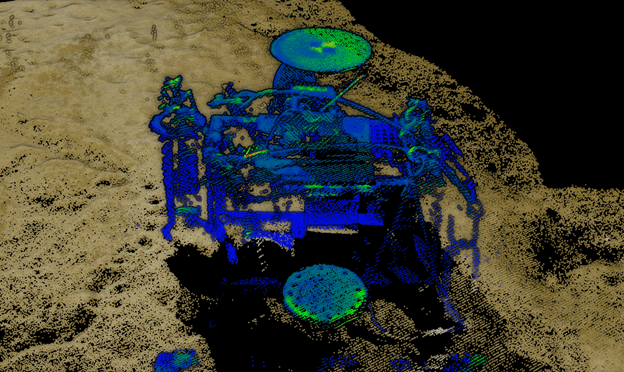

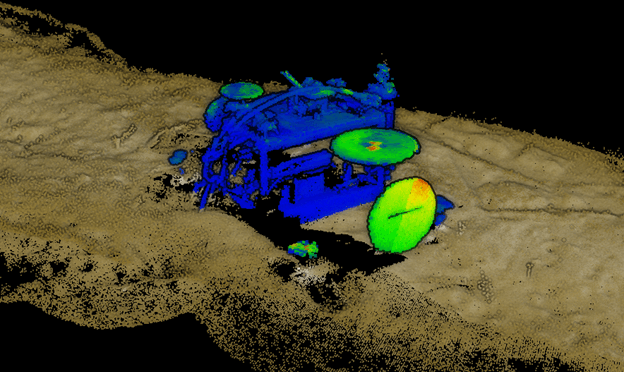

Two structures each containing four flanges were placed on the seafloor with an approximate baseline distance of 18m

The control measurement for the analysis was established by a LBL acoustic technique with flange orientations provided by installed gyro frames

The Insight Pro was mounted at 30° to capture the side facing hubs, upward facing hubs, and seabed in a single scan pass over the 18m baseline

With each scan run taking only 4 minutes, the ROV performed multiple redundant runs from structure-to-structure at an altitude of approximately 3m

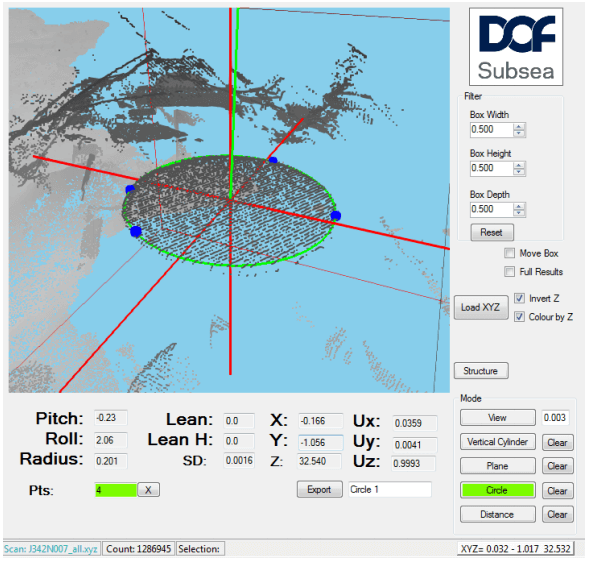

The data was transmitted to the surface in real-time, processed through EIVA navigational software, and then through DOF’s Metro Prep software for automated metrology analysis

From these high-resolution point clouds, exact measurements can be taken to facilitate the fabrication of spools and jumpers while concurrently providing as-built condition assessments

Final Results

Four runs were performed at 4 minutes a run. The measurements of the vertical jumper metrology and the horizontal spool metrology were within accepted industry tolerances.

The results of the trial highlighted the following key benefits of Dynamic Laser Scanning for metrology applications:

Reduced Survey Time

Significant reduction in the time to gather the data when compared to other techniques.

Real-time data

Delivery of final metrology measurements offshore within hours of data acquisition.

Contactless

No physical interaction with assets is required.

Flexible deployment

Configurable mounting orientations on ROVs for specific survey applications

More than metrology

The 3D model used for metrology serves as an As-Built model of the subsea installation and the surrounding area to provide a baseline for future intervention work.

Hours or less time-to-measurements

Minutes or less to collect data

Spool and Hub Metrologies with Dynamic Laser Scanning

Results

WARNING - LASER RADIATION - AVOID EXPOSURE TO BEAM

Class 3B Laser Product

448nm, <75mW, 1mSec to CW

EN/IEC 60825-1 2014

Expand the capabilities of your underwater vehicle

Speak to a member of our team to learn more and get started with your project.

We provide versatile optical solutions to expand your underwater capability and enhance understanding of remote, challenging environments.

Proudly made in Canada 🍁

Contact Us

120 Randall Dr, Unit E

Waterloo, ON

N2V 1C6